About Facilities

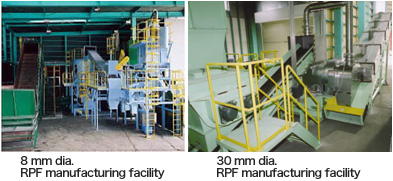

RPF Production Facility

Features

Objects sorted at the sorting facility are all crushed by a crusher to a size of 35 mm or less, sent to a volumetric feeder, and fed to a volume reduction solidification machine that utilizes frictional heat generated as a result of the rotation of the machine and manufactures refuse paper and plastic fuel (RPF). Manufactured RPF is air cooled for a certain period in a cooler and stored in a yard provided with fire protection equipment. Finished RPF is used for a variety of heating materials, reducing agents, and boiler fuel to substitute fossil fuel.

Outline

| Type | RPF facility (with compressed volume reduction) |

| Place | 2441-5, 2441-9, and 2441-11 Shidenoki, Hatta, Iga-shi, Mie |

| Installation date | July 23, 2004 |

| Processing capacity | 10.3 t/day (8 mm dia. RPF) 19.7 t/day (30 mm dia. RPF) |

| Processing type | Compression volume reduction machine |

| Types of waste handled | Waste plastics and waste paper |

-

(1) Volumetric feeder

Objects sorted at the sorting facility are all crushed by the crusher to a size of 35 mm or less, sent to the volumetric feeder, and fed to the volume reduction solidification machine.

-

(2) Volume reduction solidification machine

The volume reduction solidification machine utilizes frictional heat generated as a result of the rotation of the machine and manufactures RPF.

-

(3) Silo cooler

Manufactured RPF is air cooled for a certain period in the cooler. Finished RPF is shipped to paper mills and steel plants.

-

(4) RPF product (8 mm dia.)

RPF is a recycled product of stable quality ensuring ease of energy quantity control and excellent handling properties.